The type of monitoring makes

all the difference

Monitoring underground fuel tanks for leaks is not an option. It’s a federal requirement – and for good reasons. The source of drinking water for nearly half of all Americans is groundwater. Since contaminated groundwater is the greatest potential threat from a leaking UST, securely containing fuel products and other corrosive liquids is essential.

Two types of monitoring for double-wall fuel tanks fulfill the EPA requirements: hydrostatic monitoring and dry monitoring. To date, dry monitoring is commonly chosen because of cost. Today, some states are shifting toward requiring fuel installations to have hydrostatic monitoring because it provides true continuous monitoring in every single tank installation scenario.

Leaks can occur for a variety of reasons

- Aging infrastructure

- Such as with tanks susceptible to failure due to inadequate or compromised corrosion-resistance

- Improper installation or maintenance

- Such as when inspection or checks are not adequately performed

- External factors

- Such as damage caused by nearby construction or natural disasters

How does hydrostatic monitoring work?

1.

The interstice is factory-filled with a brine solution

2.

This creates a small hydrostatic pressure on both tank walls

3.

The brine solution level is monitored within a reservoir on top of the tank

4.

Any change in level – up or down – is monitored and alarmed

5.

Every incidence of a leak activates an alarm

In both dry and wet hole installations, hydrostatic monitoring is the only option that alarms in every single scenario.

Hydrostatic monitoring is the ultimate solution for the ultimate goal — to protect the health of the community and the environment — as well as a business’ operation, assets, and reputation.

What happens when a leak goes undetected?

The EPA, states, territories and tribes work with industry partners to protect human health and the environment from contamination resulting from such leaks. But what happens when a leak goes undetected?

The results can be immense and far-reaching, damaging human health, the environment, and a company and community’s business operations and reputation.

- Contamination of groundwater and water resources

- Soil contamination that makes land unusable for agriculture, recreation and any other development

- Pollution of air from gas leaks in the area

- Disruption of business operations for the tank operator – and for businesses in the surrounding area

- Costly fines and cleanup costs

- Loss of property value

- Damage to reputation – both locally and nationally

- Potential lawsuits by others impacted

Adding hydrostatic leak-monitoring and tank-tightness testing to corrosion-resistant fiberglass tank can provide the highest level of protection in fuel installations.

Proven

Performance

True Continuous Monitoring

Detects and alarms in all scenarios

Dual

Function

Leak detection & tank-tightness testing

What is the cost when a leak occurs?

State fund programs raise and spend a total of approximately $1 billion per year to remedy damage caused by these leaks. This is in addition to federal outlays from the Leaking Underground Storage Tank Trust Fund and additional amounts paid by individual parties held responsible for contamination.

The cost of cleanup depends on a variety of factors. The most significant are:

- The extent of the contamination to the groundwater and/or surrounding soil

- The amount of soil and/or water that needs to be removed and treated

- Whether resources of drinking water in area are impacted

- The cleanup standards of the state in which the leak occurs

The average cost of cleanup is approximately $154,000. When leaks affect groundwater, the additional corrective actions can cost between $100,000 to more than $1 million. Since 2002, state UST financial assurance funds have paid approximately $20 billion to clean up leaking UST sites.

– According to the Association of State and Territorial Solid Waste Management Officials (ASTSWMO) State Fund Survey

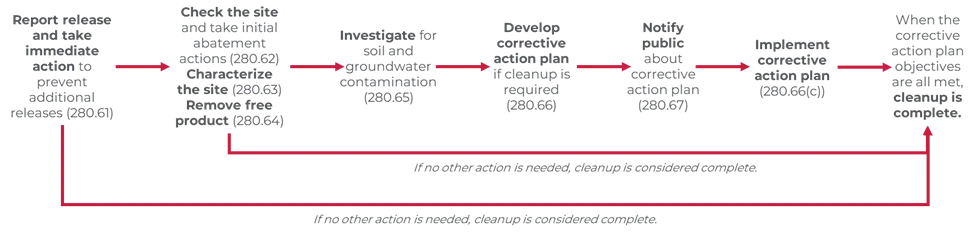

When a leak occurs the

Correct Action Plan is long

and complicated

- Requiring a multistep process

- Involving multiple people & organizations

- Taking months to years

- Costing hundreds of thousands to millions of dollars

Source: 2025 EPA Website

Truchek® Hydrostatic Monitoring meets every EPA leak-detection requirement

- Detection of a leak from any portion of the tank that routinely contains fuel

- Leak detection that is installed and calibrated in accordance with the manufacturer’s instructions

- Leak detection operated, maintained, and tested in accordance with the manufacturer’s instructions

- Leak detection using one of the seven methods described in the federal regulations (Section 280.43)